0 1 .

Light steel villas, also known as light steel structure houses, are mainly made of hot-dip galvanized steel strip and cold-rolled light steel keel. After accurate calculation and the support and combination of accessories, they play a reasonable bearing capacity to replace traditional houses.The construction technology of low-rise residential buildings with light steel structure is evolved on the basis of North American wood structure construction technology. After more than one hundred years of development, a mature construction system with excellent physical performance, flexible space and shape, easy construction and various forms has been formed. Known as the best living environment in the world, North America mainland and even Japan and Korea have more than 95% of low-rise civil buildings, including residential buildings, shopping malls, schools and office buildings, are constructed with wood or light steel structures. North American wood and light steel structures occupy an absolute advantage in the whole construction market.At present, with the rising timber prices and the increasing awareness of human environmental protection, the market development of North American light steel structure system is growing rapidly at a growth rate of more than 30%. It is gradually widely accepted by the market. At the same time, it is widely used in Japan, Korea and Australia.

The reasons for the rapid development of light steel structures in North America can be summarized as follows: mature and reliable technology, flexible structure system conducive to construction and commercial development, high building economy, advanced technology in line with the trend of environmental protection, energy conservation and sustainable development, which has the following six advantages

The technology and product configuration of light steel structures are very mature and highly industrialized, which is the crystallization of the development of construction technology and building materials industry in North America in recent 100 years. Galvanized steel sheets used in building structures have excellent corrosion resistance and durability. Their service life under normal conditions is 275 years.

ecause the weight of light steel structure is light, the weight of unit area is only 1/4 of the weight of brick-concrete structure of the same area, so its foundation treatment is simple and suitable for most geological conditions. At the same time, steel structure residence is no longer as worried about termites as wood structure residence.

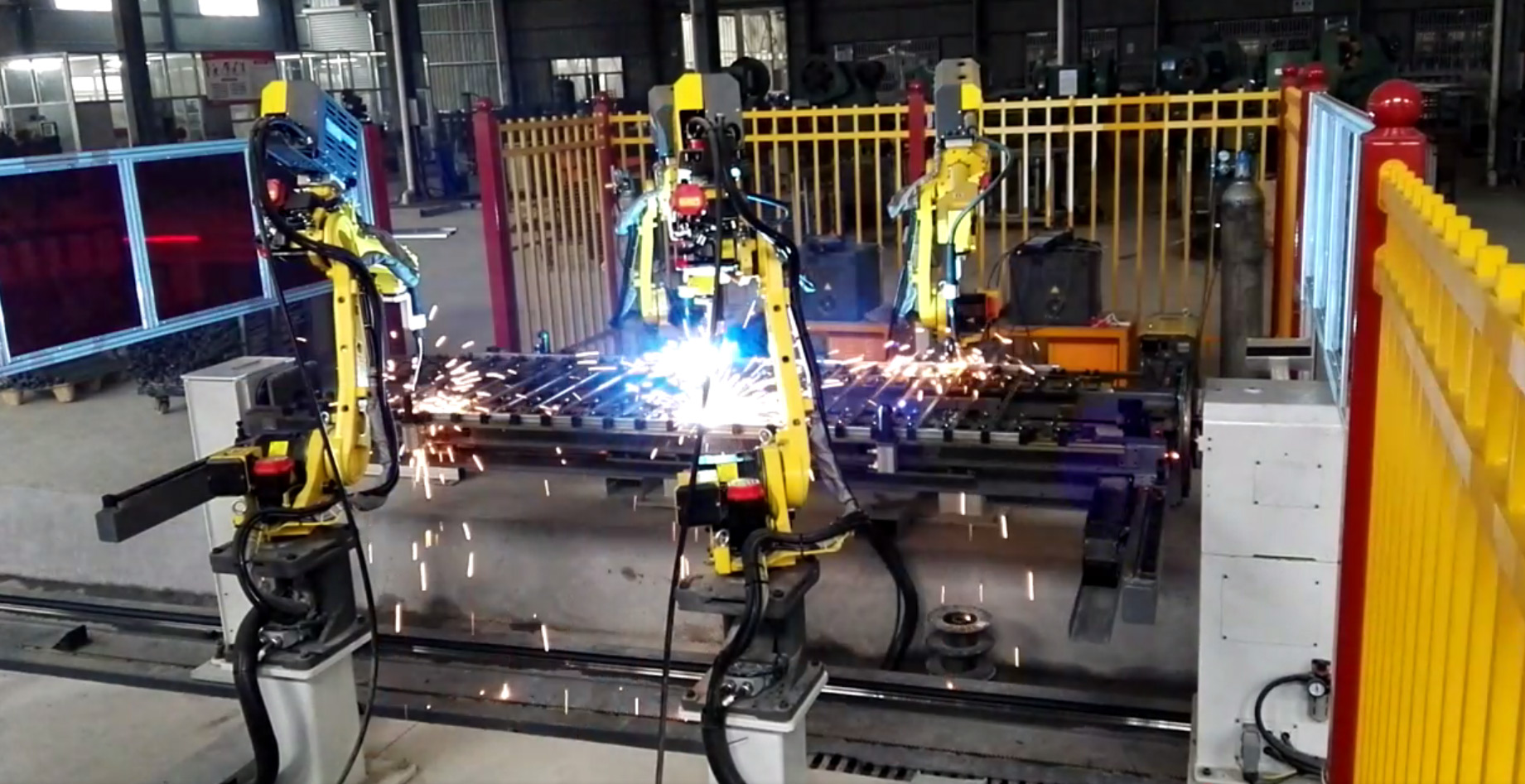

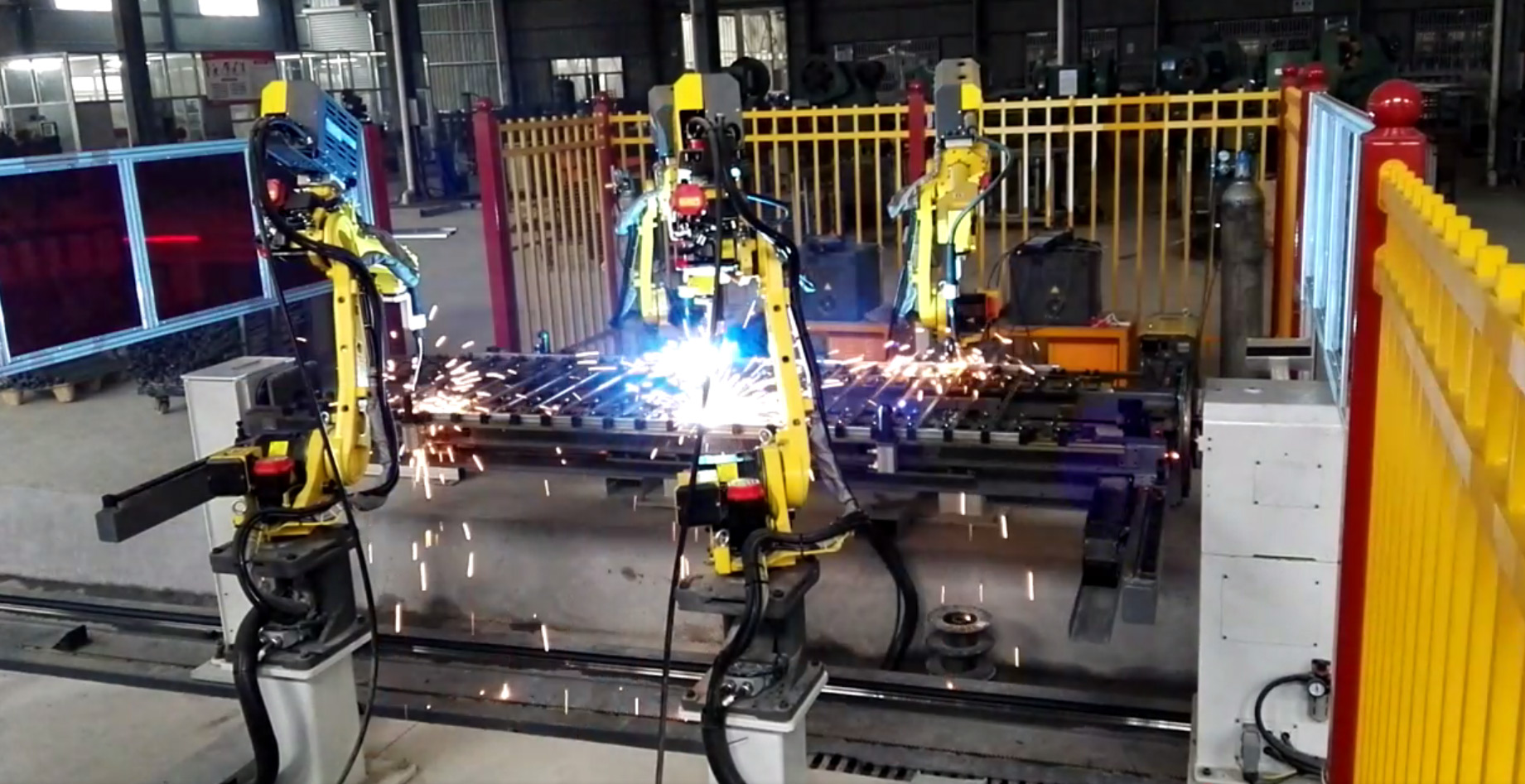

Because the steel materials used in the structure are processed by factory, the structural accuracy of light steel structure villas is quite high. The structure system of a villa is composed of ten thousand components. The average error of each component is less than 2 mm, which ensures the quality of the house. It is beyond the reach of traditional building methods.

Because of the light weight of light steel structure building, the properties of metal materials and the necessary form of shear wall structure, the inherent aseismic and wind-proof performance of light steel structure system is determined. Because the seismic activity is left and right and up and down, the light steel structure with fasteners constitutes a safe and stable box, which will not cause wall collapse or floor falling due to the shaking of the earthquake and endanger personal safety. When the earthquake intensity is magnitude 9, it can meet the requirements of non-collapse, and at the same time, the wind-resistant load can reach typhoon category 12 (1.5KN//㎡)

In addition to filling glass fibre in the structure wall, a layer of heat preservation material is put on the outside of the wall to effectively isolate the thermal bridge from the wall pillar to the outer wall panel; glass fibre is filled in the shelf between floors to reduce the heat transfer through the grate; glass is filled in all interior walls. Glass fibers, reduce the heat transfer between the walls. The insulation layer also allows the building to have a wall sound insulation ≥45 dB and a floor impact sound pressure ≤70 db. According to the global climate zone and user sound insulation requirements, the thickness of the insulation layer of the external wall and roof can be arbitrarily changed.

Compared with reinforced concrete residential buildings, light steel villas can be recycled because the steel of light steel structure can be used later, but the concrete can not be recycled. It will definitely be construction waste in the future, resulting in environmental pressure; compared with brick-concrete residential buildings, light steel villas can avoid the wave of resources caused by burning bricks with earth. Because the wall thickness of the light steel structure is small, it can increase the effective use area than the brick-concrete structure; the construction of the light steel villa adopts the dry construction method, which is hardly affected by the weather and will not cause waste of water materials; at the same time, the construction speed of the light steel villa is fast on the spot, and after the foundation is completed, only according to the villa area is different. It takes 6-8 workers 45-90 days to complete all the structural construction and internal and external fine decoration. At the same time, the non-use of heavy equipment during construction will not affect the nearby residents, which is conducive to civilized construction, and the construction cost is not higher than other traditional construction methods such as reinforced concrete.